€ 197,00

material

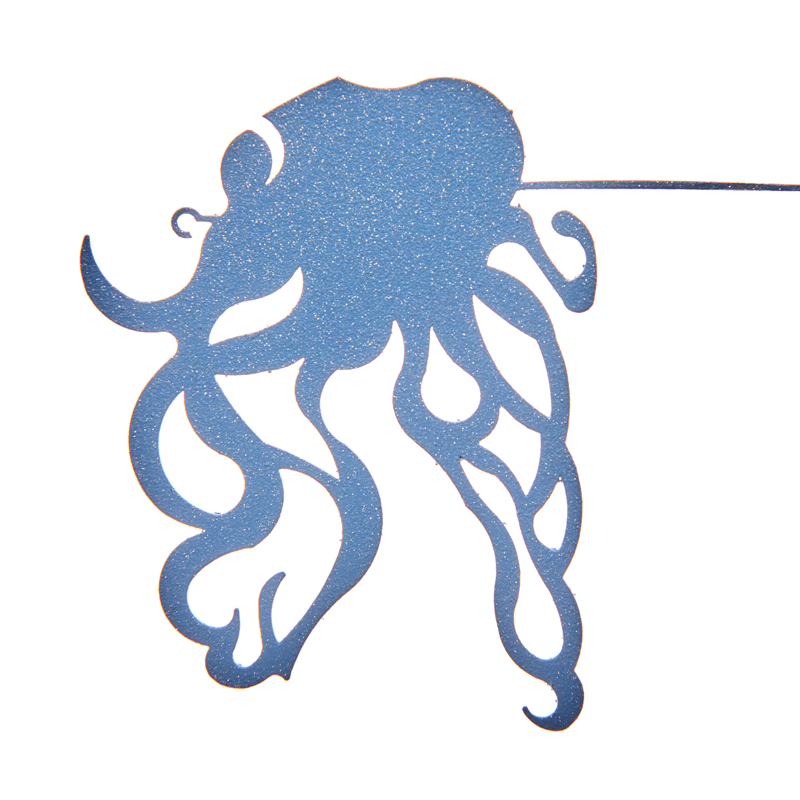

- Lasercut stainless steel: deburred, sandblasted, polished, Needle ground and bent

- powder-coated with TIGER Drylac® 3D Metallics

- Special TIGITAL TATTOO® process

- Colors: Azzurro (pastel blue) | Azzurro (sapphire blue) | Highland (reed green) | Marrone (champagne)

- size: 9 * 7 * 0,3 cm

- with black cardboard/ foil

- limited edition to 99 pieces!

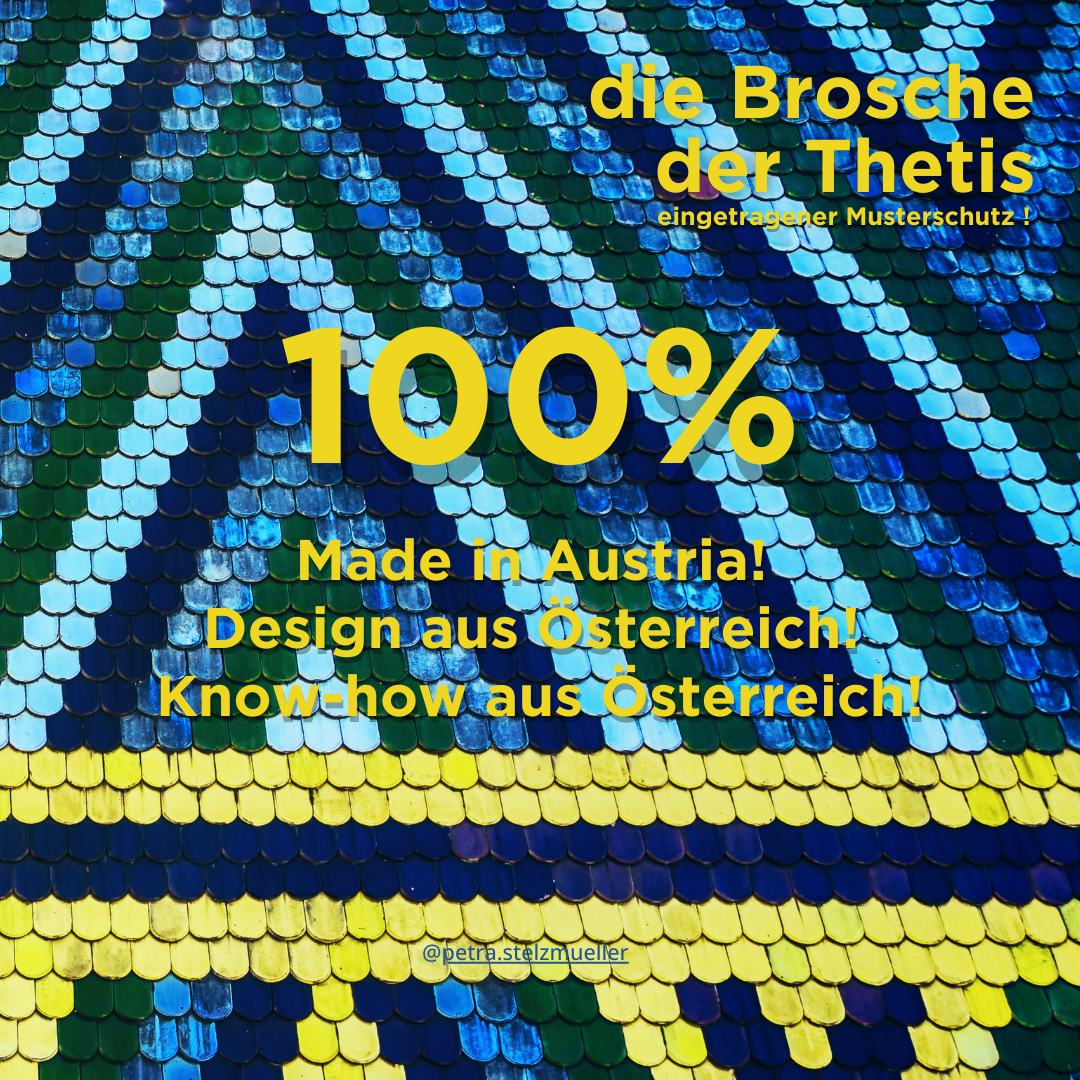

- 100% design from Austria!

- made in Austria!

- registered design copyright

- GERMAN DESIGN AWARD special mention 2023

- BIG SEE Product Design Award Winner 2023

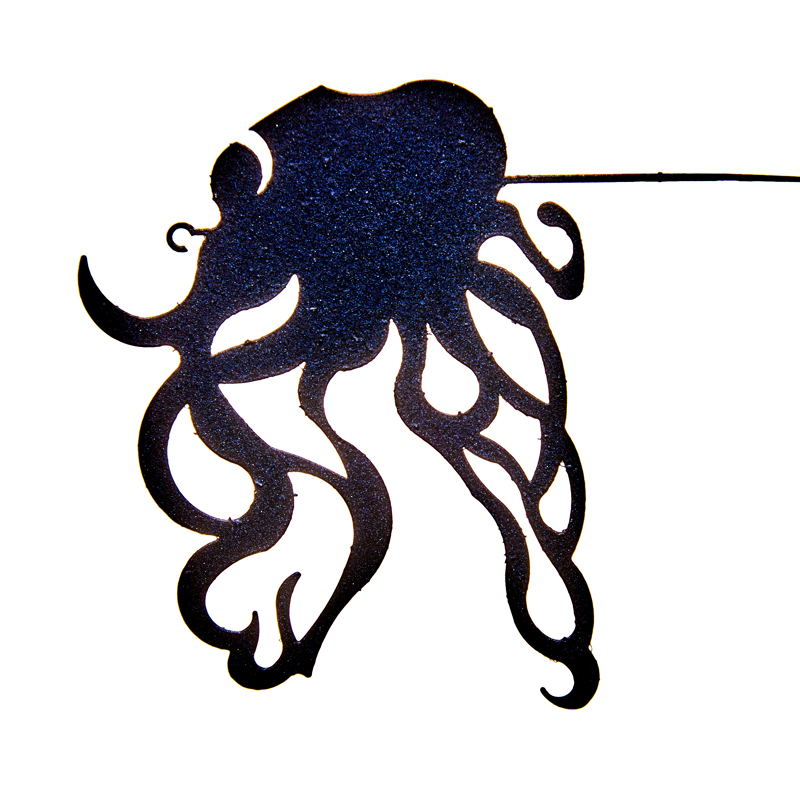

Description

In dealing with the exhibition objects for IRON MEN in the Kunsthistorisches Museum, I was not only concerned with the weapons and knight’s armour, but also with their engravings and ornaments on the artistically crafted equestrian armour. In the process, I found some interesting details, such as the ornament with the fire plates and flames in the boy’s cuirass of Karl V.

With the brooch of THETIS I wanted to create something new according to the time and varied with the outlines of the fire plates and its flames. These appeared to me more like the tentacles of an octopus and I complemented the octopus with eight “feet” (Greek: októ poús) as well as an eye on the side, a figure emerged like that of Thetis, the shape-shifter.

In the manufacturing process, a 0.6mm stainless steel plate is inspected for flawlessness and placed in the laser machine. The parts are lasered out, inspected, de-scratched, sandblasted and inspected again. The next step is to grind and bend the brooch pins.

If the brooches are still powder-coated with a color, they must be hung on hooks that are guided over a rail. The parts are first chemically pre-cleaned, rinsed and dried at 50° C in the oven. In the next step, the desired color is applied and dried over the rail in the oven at approx. 200° C for half an hour. In the next step, the desired color (TIGER® Drylac powder coatings series 68) is applied using an electrostatic powder spraying machine and burned and dried in the oven at approx. 170° C for half an hour. With the TIGER® Drylac powder coatings series 68, a very exclusive surface finish is possible, which has a special grain size and is scratch-resistant. The coating is also color-stable and offers corrosion protection.

Tigital® Tattoo

After the brooch has passed through the powder coating process, the desired images are prepared using a special printer. The printed roll is then inserted into the transfer machine, the brooch is placed and the silicone pad heats up to a surface temperature of approx. 120°C and transfers the film to the brooch for 3 seconds. In the convection oven, the brooch is hardened at 175°C and is also scratch-resistant. The St. Stephen’s Cathedral photo is now placed using Tigital® Tattoo. More about the story “the brooch of Thetis” more information on Instagram

I would like to thank the Kunsthistorischen Museum Vienna and Tiger Coatings GmbH & Co. KG AUSTRIA for the successful cooperation!

– made in Austria!

– 100% Design aus Österreich!

– 100% Know-how aus Österreich!

– registered design copyright

– GERMAN DESIGN AWARD special mention 2023

– BIG SEE Product Design Award Winner 2023

Additional information

| Weight | ,011 kg |

|---|---|

| Dimensions | 9 × 0,3 × 7 cm |

| colours on back | Azzurro (pastel blue), Azzurro (sapphire blue), Highland (reed green), Marrone (champagne) |

Product safety

Safety instructions

Brooches that are fastened with pins usually cause corresponding cavities, depending on the tightness of the fabric/carrier fabric.

Manufacturer information

design petra stelzmüller, Vienna

You may also like…

-

brooch of THETIS

€ 74,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS limited edition stainless steel

€ 149,00incl. 20% VAT

Add to cart -

brooch of THETIS stainless steel powder coated

€ 108,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page

You may also like…

-

brooch of THETIS

€ 74,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS stainless steel powder coated

€ 108,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS limited edition stainless steel

€ 149,00incl. 20% VAT

Add to cart

You may also like…

-

brooch of THETIS stainless steel powder coated

€ 108,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS

€ 74,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS limited edition stainless steel

€ 149,00incl. 20% VAT

Add to cart

You may also like…

-

brooch of THETIS

€ 74,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS stainless steel powder coated

€ 108,00incl. VAT

Select options This product has multiple variants. The options may be chosen on the product page -

brooch of THETIS limited edition stainless steel

€ 149,00incl. 20% VAT

Add to cart

Reviews

There are no reviews yet.